מונוכרום Shift+A

ניגודיות כהה Shift+S

ניגודיות בהירהShift+D

הגדל גופן Shift+F

הקטן גופן Shift+Z

הדגשת קישורים Shift+X

איפוסShift+C

הצהרת נגישות

© כל הזכויות שמורות 2018

הצהרת נגישות

© כל הזכויות שמורות 2018

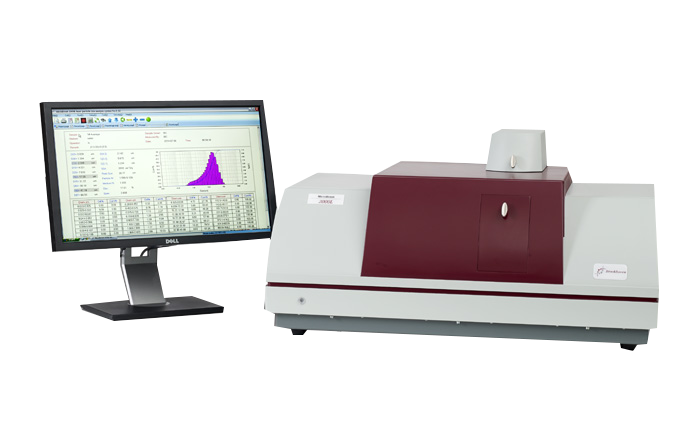

Features For generations particle sizing was determined by sieving, sedimentation & electro- or optical zone counting. These classical techniques still have their place, but for speed, repeatability, simplicity of automated operation and broad size ranges, laser diffraction and scattering dominate in this area of particle characterization. Brookhaven’s new offering, the MicroBrook 2000L, continues the domination. The MicroBrook 2000L utilizes a unique single-beam, a dual-lens system that receives all the scattered signals emitted from particles in the nanometer to millimeter size range. Employing the highest quality lenses results in high-resolution imaging of the diffracted and scattered light with low distortion, ensuring that the instrument will receive all signals – even weak signals at high angles from scattering of the smallest particles.The intelligent design of the Standard Operating Procedure (SOP) selections allows editing, storing, and recalling SOPs in order to automate routine measurements. A large number of different particle chemistries are pre-loaded including refractive indexes (for accurate Mie calculations of size distributions below a few microns) and particle densities. Other SOPs can be generated by the user. The MicroBrook 2000L is a turn-key instrument. Its operation is as simple as adding the sample to the instrument. Then the internal sub-systems will automatically take care of the rest: supplying liquid medium, dispersing (stirring, sonication), circulating, adjusting concentration, measurement (and repeats), rinsing, cleaning, printing, and saving. For example, if the concentration is too high, the instrument will automatically dilute the sample; and if the concentration is too low, the MicroBrook 2000L will alert the user to add more sample. The benefit of an automated instrument is not only its simple operation, but a reduction in human error that improves the accuracy and repeatability of the measurement. Reproducibility from instrument-to-instrument is achieved using a standard reference material supplied with every instrument. It is also useful in validating that an instrument is working properly. Such procedures are automated and calibration is performed automatically. Alignment of the incident laser beam is critical for accurate particle size distribution measurements. To ensure perfect alignment, the MicroBrook 2000L uses an automatic focusing system that consists of: a precise stepping motor, automatic focusing system, precision guide rail, lead screw, connecting axle, and subdivision controller. The internal circulation, dispersing, and alignment systems are all automatic in the MicroBrook 2000L. The ultrasonic dispersion unit can operate with a dry sample tank, the liquid suction pump can operate even with an empty liquid reservoir, and a level sensor ensures no overflow of liquid. In addition, a stainless steel tank and valves including a corrosion resistant tubing add to the durability of the instrument. A specially designed photoelectric detector array that includes 90 detectors guarantees the scattered signal of each particle will be received. This ensures that a broad size range is measurable with the resolution expected from a high-end particle sizer like the MicroBrook 2000L.

For more Information About MicroBrook 2000L