מונוכרום Shift+A

ניגודיות כהה Shift+S

ניגודיות בהירהShift+D

הגדל גופן Shift+F

הקטן גופן Shift+Z

הדגשת קישורים Shift+X

איפוסShift+C

הצהרת נגישות

© כל הזכויות שמורות 2018

הצהרת נגישות

© כל הזכויות שמורות 2018

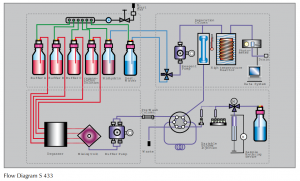

Innovative automatic Amino Acid Analyzer S 433 combines the advantages of the classical ion exchange separation method with the modern technique of high performance liquid chromatography.

The innovative automatic Amino Acid Analyzer S 433 combines the advantages of the classical ion exchange separation method with the modern technique of high performance liquid chromatography. The

complete package of sophisticated instrumentation, a wide variety of prepacked and tested separation columns, combined with optimized ready-to-use buffer solutions and chemicals, creates the right answer for any routine or research problem in amino acid determination. More than 30 years experience in developing and operating sophisticated amino acid

analyzers results in unmatched performance.

Multistep Separation

Only two or three buffer solutions have to be combined to form the best optimized buffer profile at any part of the separation program. No more compromises by the limitation to four or five buffer changes.

Cooled Reagent Storage

All buffer solutions, as well as the Ninhydrine reagent are stored under inert gas pressure in a refrigerated cabinet to avoid oxidation and air contamination independent of the ambient environment.

Integrated Autosampler

with a capacity of 120 vials in a cooled sample tray. Volumes from 1µl to 100 µl can be injected without any loss of sample. The injected volume is adjusted by a high precision syringe, driven by a stepper motor with a resolution of 17 steps per µl. A programmable wash program

will flush the entire injection system to avoid cross contamination of the sample.

Integrated Vacuum Degasser

avoids the interruption of the buffer pump by air bubbles without the need of bubble traps with varying volumes, causing changes in retention times of the different amino acids.

Separation Column Oven

integrated solid state column oven with fast heating and cooling capability with a temperature range from +20°C to +99°C independent of the ambient temperature. Up to twelve programmable temperature steps can be used

during one separation program.

High-Temperature Reactor

with a programmable temperature range from ambient to 180°C with a coiled capillary for the color reaction of the amino acid-ninhydrine complex. Automatic flushing of the reactor coil with a washing solution after each run prevents the blockage of the capillary.

Integrated Reagent Dosing Pump

for Ninhydrine delivery and flushing of the reaction coil after each run. Programmable flow rate from 0.01 to 2.0 ml/min.

Complete Inert Design

All materials coming into contact with the buffer solutions and reagents are made of inert materials as PEEK, PTFE, PVDF etc. Therefore, there is no need for using special non-corrosive buffer compositions or reagents.

Integrated Dual-Channel Photometer for the amino acid detection at 440 nm and 570 nm wavelengths. Summing option for both channels, for

single channel integration of all amino acids.

Safety Devices

control pump pressures, temperatures and leakages.

Optional Application

– Post column derivatisation with OPA (needs an optional

Fluorescence Detector)

– Carbohydrate determination for reducing sugars with

Cu-bicinchoninate post-column derivatisation (except the

separation column, no additional extras are needed)

– Polyamine determination with Ninhydrine or OPA postcolumn derivatisation.

For more information about SYKAM S 433 Automatic Amino Acid Analyser